Research Program

Finally, the time had come in 2005. After two years of development and many tests, for the first time in the world a wall was successfully printed with concrete mortar in one working step. In two hours, a structure 3.5 meters long, over 2 meters high and 15 cm wide was created from dry dust. Made with the High Tech Beamix mortar & equipment technology of the time and a hand-operated printer! 3D printing of concrete was born. Since there was no market demand and nobody knew what else we could do with this, the project and the mortar were shelved. It took another 10 years before the time and the market were ready for this innovative technology.

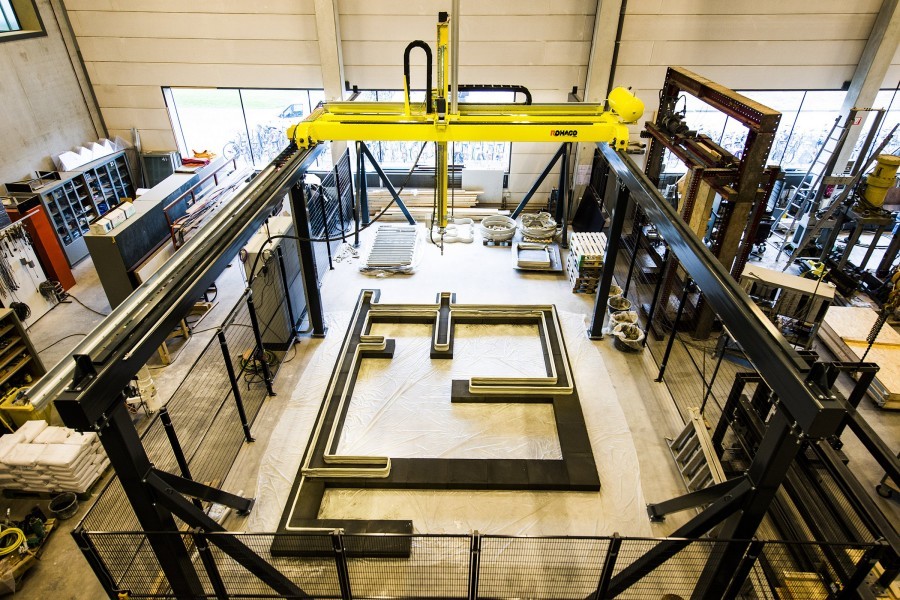

3DCP

In 2015, Eindhoven University of Technology launched the 3D Concrete Printing (3DCP) research program. To fund and carry the 3DCP program, TU/e found a group of contractors, building material suppliers and engineering firms. Saint-Gobain Weber Beamix is of course not to be missed in this selection. After all, the inventor of dry mortar brings not only mortar technology, but also the knowledge and experience in the field of mechanization and pumping.

But the partners wanted more than this. Fundamental research and experimentation led to predictability in the behavior of material and equipment, under varying conditions. This has ensured that structural elements and structures are now produced responsibly.

Watch the extensive here video.